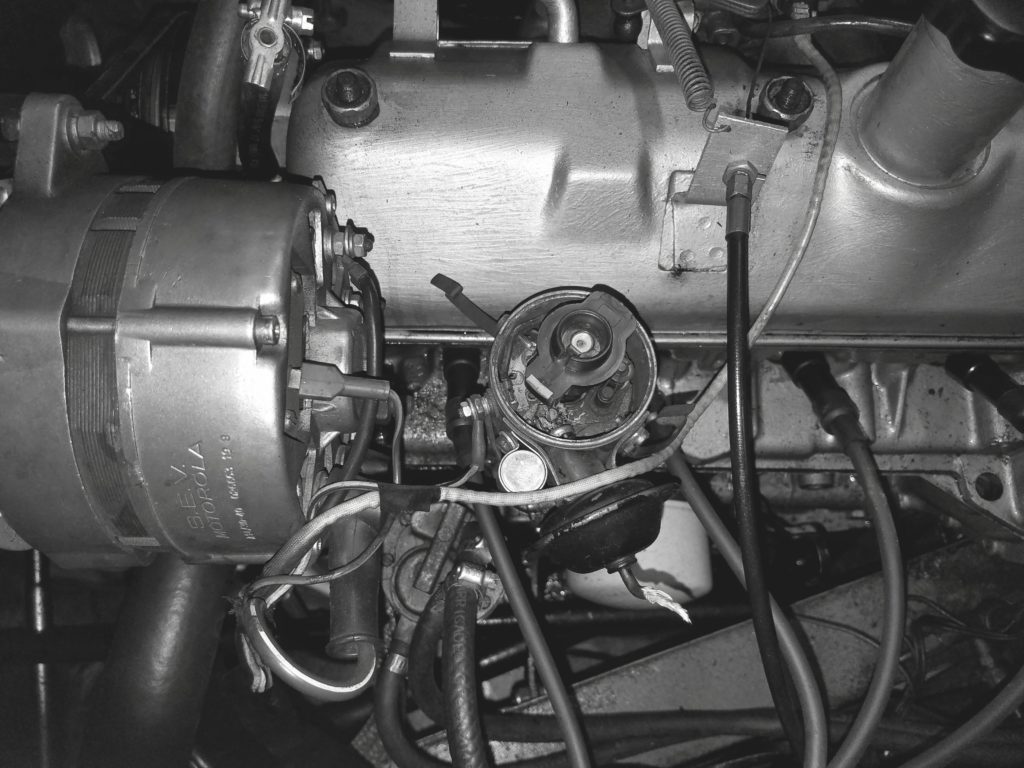

During the bad old first year that I owned my Lotus Europa the problems came fast and thick. The last owner got it running and paid to polish the paint and likely held his breath and crossed his fingers that it would work long enough to be sold. The car lasted about a week before it put on it’s true state as a mechanics training opportunity. It was a mess.

One of the systems that I spent time correcting was the ignition. I opened up and cleaned the switch then replaced it. I built new ignition wires for the coil and spark plugs – correctly. All the electrical grounds were cleaned and in some cases undone and put together right. This meant creating a frame access hole. It also created an opportunity to swap out and rewire the dash. I’d refinished one five years before so that got pressed into use.

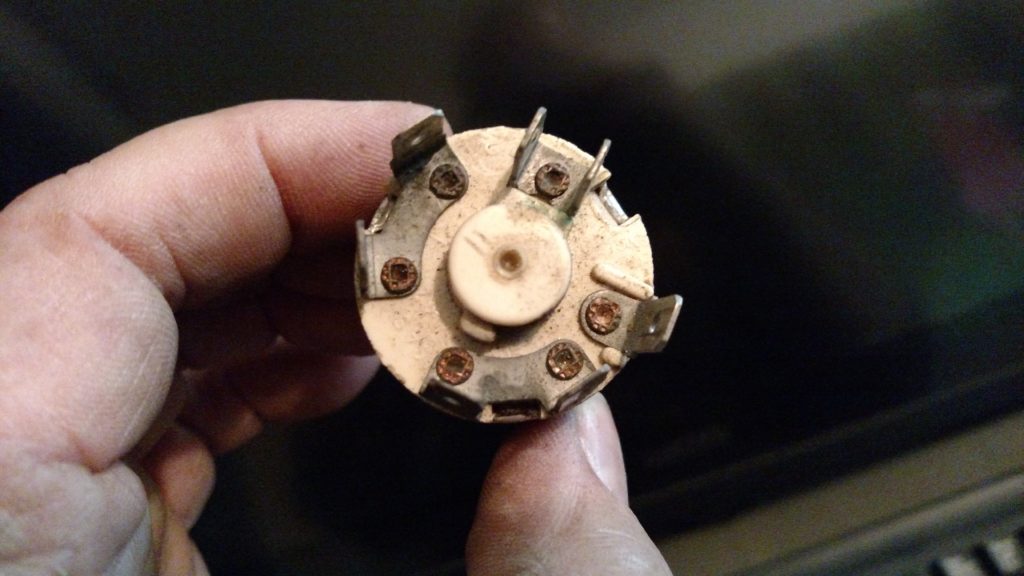

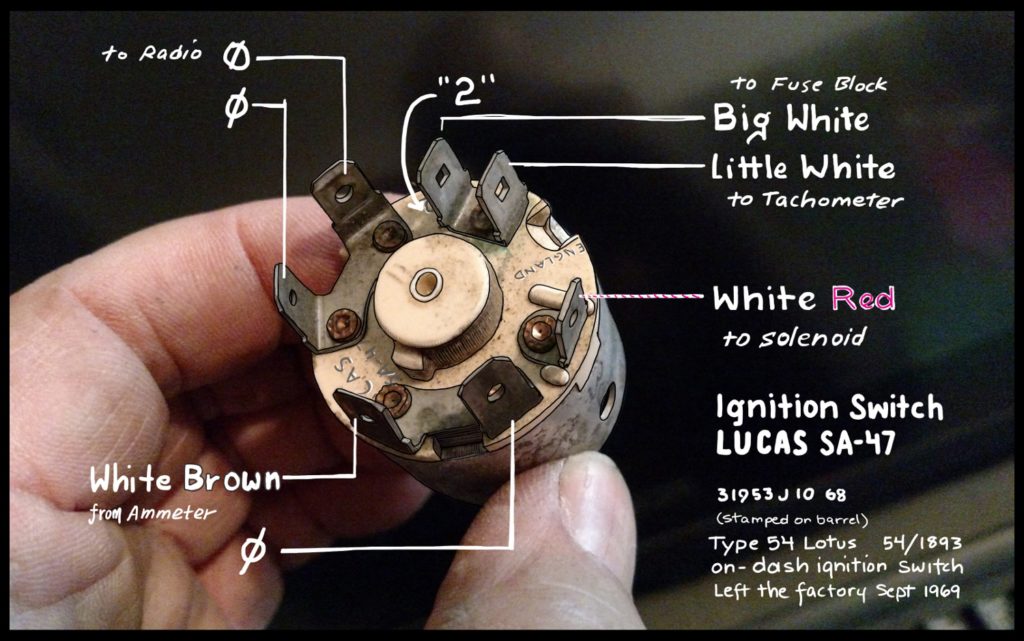

original ignition switch

ignition switch

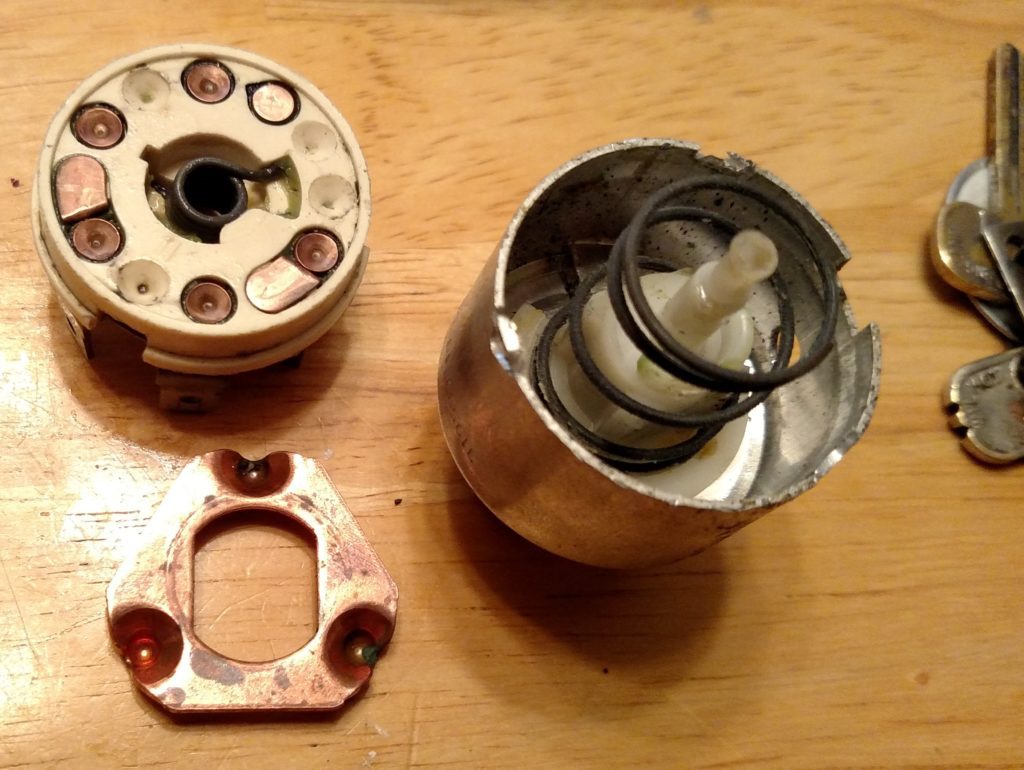

dirty fouled innards of original ignition switch

cleaned up old ignition switch. It could work. I wasn’t sure I had the triangle oriented correctly so I bought a new one.

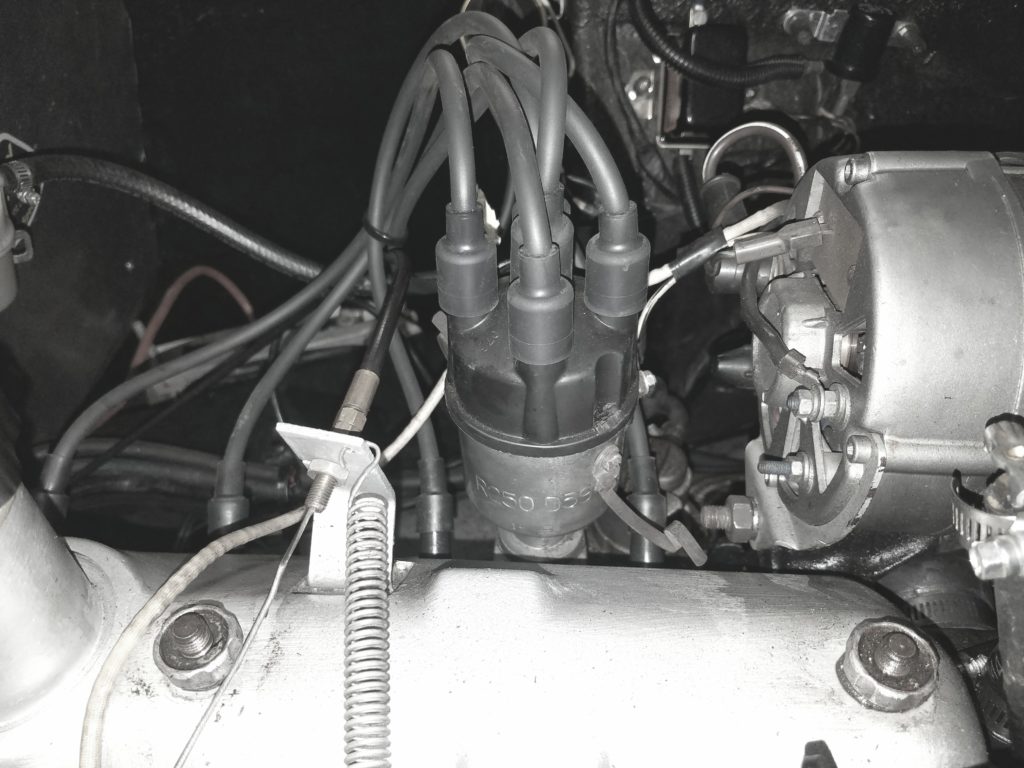

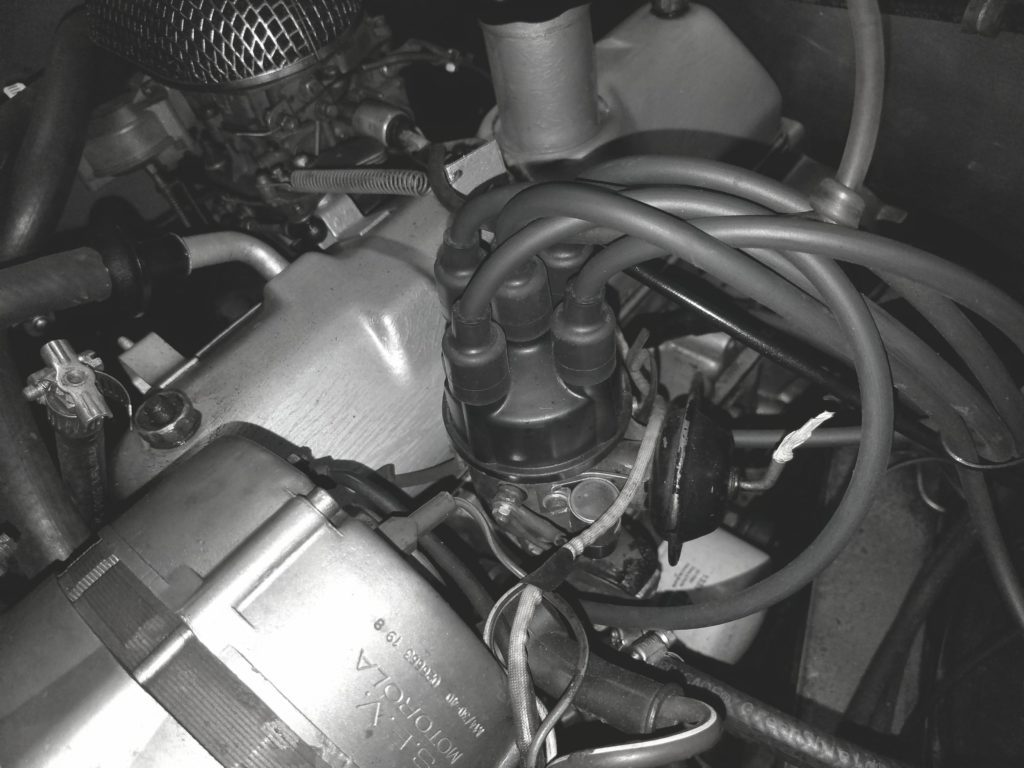

I tried an electronic ignition but couldn’t get the timing to stay set. Later I realized that the hold down bolt was trying to bite into mangled threads so I sunk a stud in it’s place and secure the distributor with a nut and now the timing stays put. Meannwhile, I couldn’t figure out how to swap the points and condenser back in so I nabbed a different Ducellier distributor that did have points from 952R, the one I bought first. I ran that awhile. When the car began to finally work the way it is supposed to, there was still some pinging under load so I rebuilt each distributor and put them with the car they came in. That would restore factory mechanical advance characteristics to each.

To my surprise, it was simple to disassemble and rebuild the units. I got in there and saw how the mechanical advance works and realized why it was needed.

The Fuel burns at a constant rate when ignited, but at speed, there is less time to fully exploit the process of combustion, so the spark is set off earlier at faster engine speeds. That’s why it’s called advance.

So I cleaned, lubricated, and adjusted the distributors. The result was more power and better running motor.

I’m back to using points and condenser for now. I don’t trust this petronix unit. The magnet ring seems loose. I’d thought the bushings in the distributor shaft were shot, but it was the magnet ring because the distributors are both tight.

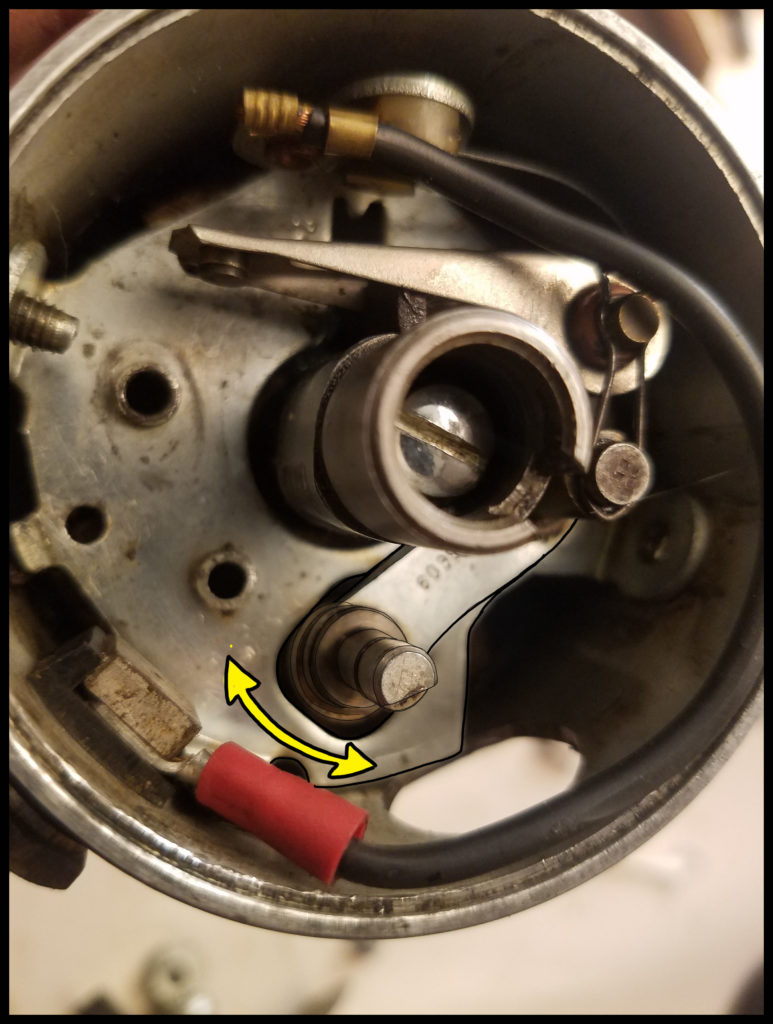

The drive dog. To get in there and pull that shaft, just work the spring off and push out the pin

R250 for the Federal car, R238 for the Type 54 European car.

The one for the Type 65 was rougher. That car spent more time in fields and being pelted with rain.

Mechanical advance for the Federal car

Mechanical advance, Federal car.

On this base sits the points and the vacuum advance

I didn’t like the look of the mechanical advance so I was even more driven to get a peek. It was just dirty. I’d tried to swab in blue grease.

why are points adjusting screws always so ravaged in the head slot?

Underside of the points pivot arm. that brass part, I concluded, was part of the path to ground.

Here I was trying to establish how to orient this arm to the vacuum unit that connects to it. thinking….

Vacuum advance. Suck on the tube and the part with the spring pulls back and alters the position of the points relative to the distributor shaft lobes thereby advancing the timing. Total advance is a result of the combination of the mechanical and vacuum advance. This screws on the side of the distributor and hooks up to the swivel base that the points slide onto

I brought in a vice and made a little distributor maintenance holder

Distributor for the older vehicle looks much nicer inside, but both are in sound, very good condition. This one is now in the car doing it’s job. I set the point gap here.

These are out of order but it matters little since most people will skim past it “cuz it’s car stuff”. Here the retaining spring is removed and the pin it keeps in place can be slid out of it’s hole so the guts of the unit can be with drawn.

What you’ll not see again, maybe ever: the underside of a mechanical advance unit in a conventional spark distributor. It’s dry, so I cleaned and lubed it up well.

distributor dog with the keeper pin exposed

This is how I took it off: one loop at a time. Didn’t hurt a thing.

It’s nice to have two distributors to compare. Much easier to know what needs replaced and how it all goes together. Modern cars are tuned via electronics and sensors. Old timers require planned component upgrades that work together to do the same thing. I’m a fan of both. The old machines really are just that – machines. Modern engine systems are marvels with their tighter tolerances, superior metallurgy, and complex mechanisms all controlled by microprocessors. To change the advance characteristics in these old things means trying different springs, different counter weights, and voodoo.